In today’s manufacturing and engineering world, the CNC machine is a revolutionary machine, transforming precision machine. Manufacturing has been redefined by CNC, or Computer Numerical Control, technology with its unparalleled precision, customization, and efficiency.

A variety of CNC machines, including aluminum CNC machines, CNC milling machines, metal CNC machines, and plasma cutter CNC machines, have played an important role in streamlining production across multiple industries. With CNC machines, manufacturing has reached a new level, offering advantages that traditional methods can’t match.

The Evolution of CNC Machines

Since CNC machines were invented, they have come a long way. Originally, the precision of modern CNC technology was lacking in traditional machining procedures, which mostly relied on manual labor and mechanical processes. The 1940s saw the introduction of numerical control, which allowed automated machinery to develop. CNC technology advanced along with computing advances during the 1970s, enabling increasingly sophisticated operations.

Precision and flexibility were greatly increased in the machining process with the introduction of computer programming. High levels of accuracy and consistency are possible thanks to the powerful hardware and sophisticated software that power today’s CNC machines. Because of this progress, producers can now create intricately detailed, sophisticated items that were previously impossible to fabricate using conventional processes.

Understanding Different Types of CNC Machines

Aluminum CNC Machines:

Aluminum CNC machines are great for working with soft metals like aluminum. They’re perfect for making detailed parts with high accuracy. Industries like automotive, aerospace, and electronics use them a lot because they can make strong but light components quickly. They’re also good for making prototypes fast and for making lots of parts at once.

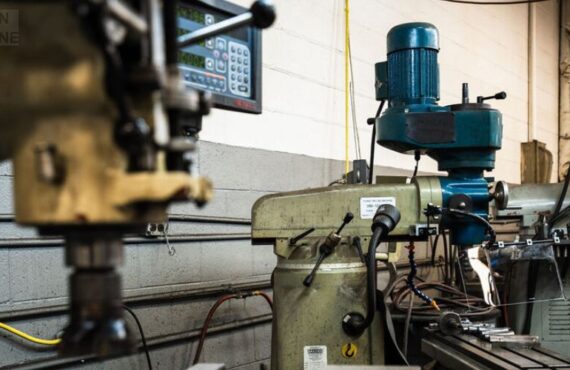

CNC Milling Machines:

CNC milling machines are flexible, moving in different directions to make accurate parts. They cut away material to make intricate shapes and details. Lots of industries like automotive, planes and medical devices use them because they can make detailed parts with very precise measurements

Metal CNC Machines:

Metal CNC machines are made of tough metals like steel, titanium, and brass. They have strong tools and systems to handle cutting through hard materials. Industries like cars, planes, and heavy machinery use them a lot to make strong parts

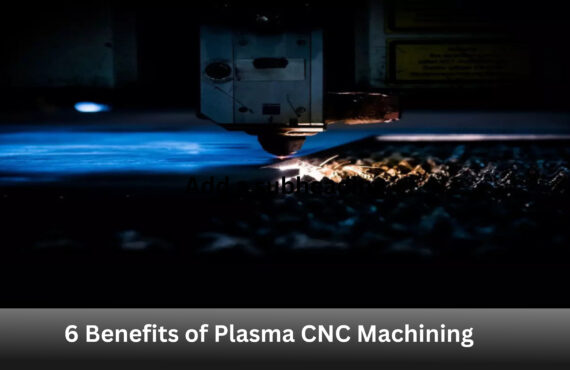

Plasma Cutter CNC Machines:

Plasma cutter CNC machines use a special torch to cut materials very accurately. They’re great for cutting metals like steel and aluminum precisely. Industries like car making and metalwork use them a lot because they cut quickly and accurately.

Precision and Customization in CNC Machining

Precision is one of the key advantages of CNC machining, allowing manufacturers to produce parts with extremely tight tolerances. This precision is crucial in industries such as aerospace, where components must meet stringent specifications. Custom CNC machining allows for the creation of tailored components that perfectly fit specific applications.

The medical device industry uses CNC machines to make special equipment that follows strict rules. In cars, CNC machines make tough parts with complicated shapes that last a long time. The precision offered by CNC machines ensures consistency in mass production, reducing errors and waste.

Why CNC Machines Trump Other Options

Compared to traditional machining methods, CNC machines offer significant advantages in efficiency and speed. They can operate continuously with minimal downtime, allowing for high-volume production. The reduction of human error is another crucial benefit, as CNC machines operate with pre-programmed instructions, ensuring that each part is manufactured to exact specifications.

Repeatability and scalability are other notable advantages of CNC machines. Once a design is programmed, it can be reproduced as many times as needed with consistent quality. This repeatability is essential for industries like automotive, where parts need to fit together precisely in assembly lines.

While other automated manufacturing methods, such as 3D printing, are gaining popularity, CNC machines still hold the edge in precision and material compatibility. CNC machines can work with a wider range of materials, from metals to plastics, making them more versatile in various manufacturing environments.

CNC Machine Trends and the Future of Manufacturing

New developments in automation and the Internet of Things (IoT) will have a significant impact on CNC machining in the future. Smart manufacturing techniques, which combine CNC machines into automated production lines, are becoming more and more popular due to automation. The production process may be optimized and monitored in real time thanks to this integration.

Industry 4.0, characterized by smart factories and data-driven decision-making, is reshaping CNC machining. The integration of IoT devices allows for predictive maintenance, reducing machine downtime and increasing efficiency. Additionally, advancements in artificial intelligence and machine learning are set to further enhance CNC machine capabilities.

CNC machines are super important in making stuff today because they’re really precise, can be customized easily, and work fast. Whether it’s aluminum or plasma cutter CNC machines, they’ve changed how industries make parts, helping them meet tough standards with great accuracy. And they’ve come a long way from just basic control to super advanced computer programming.

As CNC machines continue to evolve, their importance in manufacturing will only grow, especially with the rise of Industry 4.0 and smart manufacturing. The precision and repeatability of CNC machining make it a valuable tool for industries seeking to produce high-quality components at scale.

If you’re looking for precision and customization in CNC machining, Hamilton Machine offers comprehensive solutions tailored to your manufacturing needs. Explore their CNC machining services to elevate your production capabilities.